Manufacture

Manufacture Euramaterials

Euramaterials Manufacture

ManufactureLille metropolis, a historic industrial powerhouse

300 companies and

Alongside the textile industry, the metal, metal processing and mechanical engineering industries quickly became Lille’s 2nd economic flagship, with the flagship Compagnie Fives-Lille bridge and locomotive construction plant, which closed in the early 2000s.

Despite the decline of the 1950s, the area remained the most favourable for industrial activities to flourish, enabling them to provide20% of employment in the region today.

The essentialsin figures

World Forum Mathieu Lassalle

World Forum Mathieu LassalleFocus

Numerous technology transfer structures: CRITT, CDT, CRT, PFT, then Carnot institutes, SATT Nord, competitiveness clusters.

Renowned research laboratories: L2EP, Cristal, Laboratoire de Chimie, L’usine agile des arts et Métiers, etc.

Atelier 57: the largest SNCF train renovation centre, this 4.0 factory concentrates all the technological solutions dedicated to the renovation and modernisation of trains.

Team²: the only competitive cluster dedicated to circularity through recycling

World Forum: The World Forum for the Responsible Economy is an annual series of events designed to promote a responsible global economy by showcasing the “Best Practices” of companies operating responsibly around the world.

Textile expertise assured

The Hauts-de-France region now ranks second in France for the manufacture of technical textiles, with 3,300 dedicated jobs. (Sc CCI Hauts-de-France). It has to be said that the sector is thriving, with 21,300 hectares devoted to flax production and 17% of European textile engineers trained in the region.

In the Lille European Metropolis, 130 textile, fashion and clothing companies are listed, with a total workforce of 9,000.

In addition to the traditional garment manufacturing activities, the entire sector is being structured around eco-responsible issues. Companies in the sector, supported by CETI (Centre Européen des Textiles Innovants), are all encouraged in the circulatory and zero waste approach that is incumbent on this sector, which is responsible for 1,700,000 tonnes of waste a year.

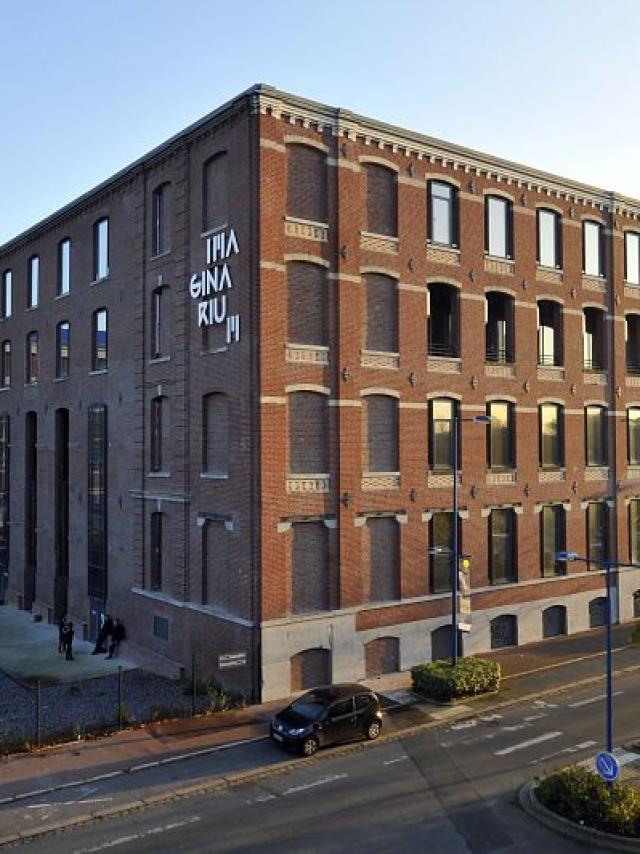

Euramaterials, a cluster serving the materials processing industries, is also supporting young initiatives in this field, bringing them to maturity through its incubation programme.

The Lille metropolitan area, cradle of the 3rd industrial revolution

As a resolutely industrial region, the Hauts-de-France is inextricably linked with an eco-responsible dynamic. At a time when the challenges of cleaner industry and a healthier economy are at the forefront of global strategies, we need to identify all the changes that are possible on our own scale.

Team², the only national competitiveness cluster dedicated to circularity through recycling, is taking student and professional engineers with it in the search for solutions, and is succeeding in convincing the major companies concerned to transform their processes.

Today, materials derived from recycling are increasingly regarded as real materials, and no longer as secondary materials. This growing awareness can be seen across the region, with the intelligent deconstruction of buildings (half of the region’s waste).

Other, younger companies are tackling the mobility segment, with the creation of traceability or data security applications to optimise the lifespan of parts and vehicles. These nuggets can be found at EuraTechnologies, a pioneering French Tech incubator that has already supported more than 300 tech start-ups.

An economy driven by more responsible players, and sustainable appliances made from recycled materials: this is the objective of the 700 eco-businesses in the region, making it the 4th French region for the green economy. This approach is directly linked to the Rev3 regional programme for a sustainable and connected economy and, at metropolitan level, the PCAET for reducing greenhouse gas emissions and energy consumption, developing renewable energies, improving air quality and adapting to climate change.

A competitiveness cluster serving the materials processing industries. It supports companies and research players, enabling them to find solutions, perform and grow.

A site of excellence in the Lille European Metropolis dedicated to fresh, local produce and its logistics. Its aim is to boost the creation of innovative businesses and jobs in the fresh produce sector in the region.

As an ecotransition accelerator, its aim is to facilitate energy and ecological transitions in the Hauts-de-France regional economy and beyond.

Approved in 2010, Team2 is the only national recycling innovation cluster that stimulates, supports and promotes industries dedicated to the production and use of new resources, thanks to its expertise and its network of industrial, scientific and institutional partners.

12,000m² at the service of companies to encourage and accelerate innovation.

It’s a place to design, experiment, prototype and industrialise new products, materials and processes tailored to the needs of the global industry. The CETI works with producers, major brands and distributors in the fashion, sports, luxury and technical textiles sectors. Its international dimension places it among the world’s top 5 technical centres.